👋 Introduction

In 2026, an HVAC business will not simply repair broken systems anymore; it will have an approach in place to ensure that systems do not break down. In this era of high energy costs, strict sustainability standards, and customer demand for efficiency, the maintenance of HVAC systems turns out to be business-critical.

According to the U.S. Department of Energy, HVAC use accounts for about 40% of energy consumption in commercial buildings. So an inefficiency of even the slightest degree would result in high costs. However, whether they are building owners or even homeowners, energy-efficient solutions are expected, as are keen response times and completely transparent service contracts.

However, while so crucial, it is not easy to maintain an HVAC maintenance schedule. Some of the problems faced by service providers include

- Manual errors in scheduling causing appointments to be missed.

- Technician accountability issues that arise from the absence of digital tracking.

- Inventory shortages causing delays to preventive service.

- Extreme seasonal demand, such as for cooling in summer or heating in winter.

This is where contemporary HVAC field service management software comes into play. It allows companies to automate scheduling, improve communication, and ensure that preventive maintenance does not go unattended.

📅 What is an HVAC Maintenance Schedule?

An HVAC maintenance schedule is an arranged plan for preventive and seasonal maintenance tasks in heating, ventilation, and cooling systems. Unlike actual emergency repairs, an HVAC maintenance schedule focuses on routine care to keep the equipment running efficiently.

🏢 Why It Matters for Small Businesses and Service Providers

- Courteously small HVAC contractors make it possible to compete with bigger players by offering uninterrupted service.

- Generates goodwill among customers by preventing sudden breakage.

- Lightens operational stress during peak times.

For example, a small service provider getting maintenance work for more than 100 AMC clients annually can avoid chaos by automating reminders using HVAC scheduling software.

⚖️ Preventive vs. Reactive Maintenance

- Reactive Repair: Costly, unpredictable, and often happens during peak season when technicians are already overloaded.

- Preventive Maintenance: Predictable, cost-saving, and improves your reputation by keeping customer systems running smoothly.

Industry Insight: Preventive maintenance reduces equipment breakdowns by up to 40% and increases efficiency by 15–20% (FacilitiesNet, DOE).

🎯 Why Following an HVAC Maintenance Schedule Matters

A well-planned HVAC maintenance schedule isn’t just good practice, it’s a competitive edge in 2026. Customers today expect energy-efficient, reliable systems backed by service providers who are proactive rather than reactive.

1. Ensures System Efficiency → Reduces Energy Consumption ⚡

The U.S. Department of Energy reports that heating and cooling account for nearly 40% of commercial building energy use. A neglected system can lose up to 25–30% efficiency due to clogged filters, dirty coils, and poor airflow.

Regular tune-ups restore performance, improving efficiency by 15–20% and helping customers save hundreds (sometimes thousands) in annual energy bills. For example, a 200-room hotel reduced its HVAC energy bill by $18,000 annually after implementing scheduled quarterly coil cleanings and monthly filter replacements.

2. Prevents Sudden Breakdowns → Improves Customer Trust 🔒

Unplanned breakdowns are costly, not only in repair but also in business downtime. A mall in New Jersey reported losing $50,000 in sales during a weekend shutdown caused by an HVAC failure that preventive maintenance could have avoided.

Hospitals, schools, and food businesses are especially vulnerable, as HVAC disruptions directly affect health and safety. Scheduled maintenance builds trust, positioning service providers as reliable partners, not emergency lifelines.

3. Extends Equipment Lifespan ♻️

Without maintenance, HVAC units typically last 10–12 years. With preventive schedules, the lifespan stretches to 15–20 years, delaying replacement costs that can exceed $20,000–$50,000 per system.

Commercial facility managers now factor this into budget forecasts. For service providers, offering longer-lasting system health becomes a key selling point.

4. Increases Technician Productivity & Reduces Last-Minute Workload 👷

Reactive jobs cause stress, poor planning, and technician burnout. Preventive maintenance evens out workloads throughout the year.

A medium-sized HVAC business in Texas reported a 25% increase in technician productivity after moving 70% of reactive calls into scheduled AMC visits. Balanced scheduling not only reduces overtime but also improves technician morale and retention.

See how you can monitor performance with Employee Productivity Tracking with Fieldy.

🧾 HVAC Maintenance Schedule Checklist for 2026

To make HVAC care structured and reliable, here’s a comprehensive preventive maintenance checklist, broken down into daily, monthly, seasonal, and annual tasks that can be easily tracked and executed using work order management.

| 📅 Task Frequency | 🔍 Details / Explanation |

|---|---|

|

🔍 Daily / Weekly Tasks |

🌀 Filter checks and cleaning: A clogged filter can reduce airflow by 20%. Daily monitoring in dusty environments (factories, warehouses) ensures efficiency. |

| 👀 Visual inspections: Spot leaks, unusual noises, or airflow issues early. Small refrigerant leaks can escalate into compressor failure within weeks. | |

| 💻 Digital logging via FSM software: Technicians upload inspection results into a shared system, creating a verifiable service trail for customers. | |

| 📅 Monthly Tasks | ❄️ Refrigerant level checks: Low refrigerant increases energy consumption by 20% and causes compressor strain. |

| 🌡️ Thermostat calibration: A 2-degree miscalibration can drive up bills by 5–10%. | |

| ⚡ Test electrical connections: Loose connections account for 30% of HVAC electrical failures. Early detection prevents fire hazards. | |

|

🍂 Seasonal / Quarterly Tasks |

🧽 Coil cleaning: Dirty condenser coils can reduce cooling capacity by up to 30%. Cleaning quarterly boosts efficiency and extends system life. |

| 🌬️ Ductwork inspection: Check for dust buildup, mold, or leaks that can reduce efficiency and pose health risks. | |

| ⚙️ System calibration: Prepares units for seasonal load changes.

Example: Schools schedule heating checks in September, before winter, and cooling checks in March, before the summer semester. |

|

|

📊 Annual Tasks |

📊 Comprehensive system audit: Evaluate system performance, compliance with ASHRAE standards, and energy benchmarks. |

| 🔧 Replacement of worn-out parts: Belts, capacitors, and filters, low-cost items that prevent costly failures. | |

| 🌍 Energy audits: In 2026, sustainability matters more than ever. Businesses completing annual audits can qualify for certifications like LEED or Energy Star, attracting eco-conscious tenants and clients. |

Organize these workflows easily with work order management. ⬇️

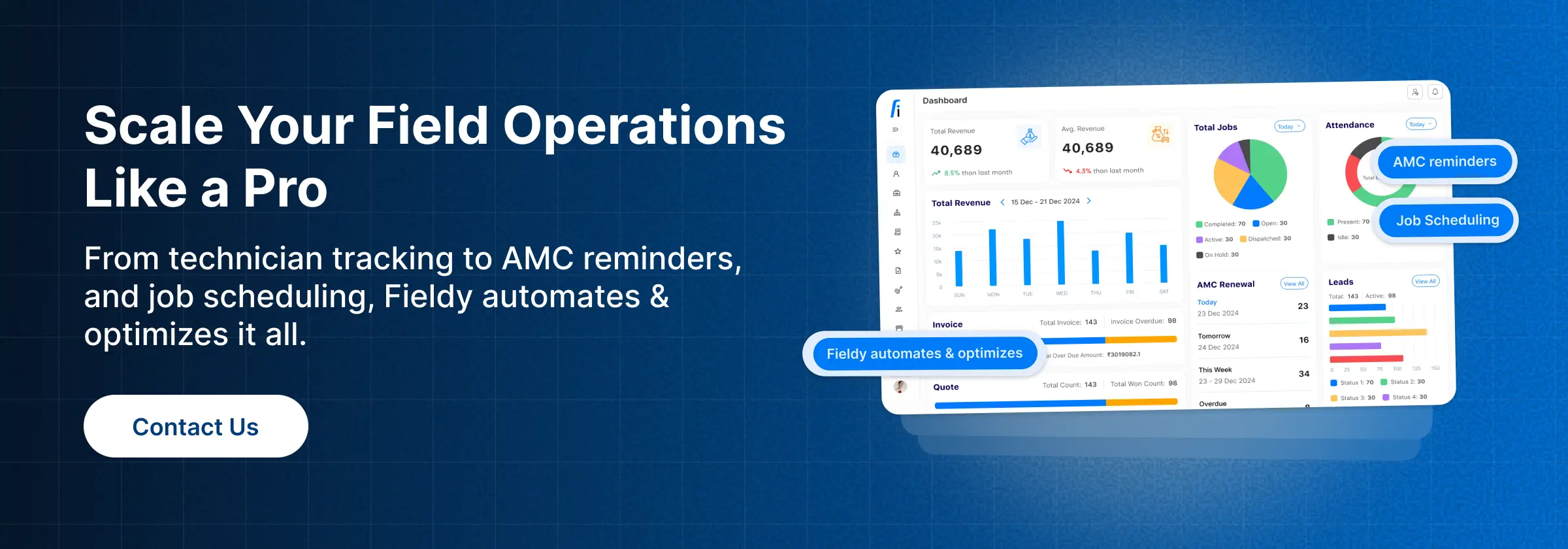

🤖 How HVAC FSM Software Helps Automate Maintenance Schedules

In 2026, juggling spreadsheets and phone calls isn’t enough. Customers expect automation, reminders, and real-time updates. That’s where HVAC FSM software changes the game.

1. Preventive Maintenance Reminders ⏰

Keeping preventive maintenance consistent is one of the biggest challenges HVAC businesses face. Customers often forget service dates, while technicians juggle multiple clients and tasks. Field Service AMC Software solves this with automated scheduling, ensuring no service is missed.

- Automated notifications: Customers receive reminders via SMS, email, or app alerts before their service is due. Technicians are notified simultaneously, reducing no-shows and last-minute rescheduling.

- Service history tracking: Every past service, part replacement, and repair is logged digitally. This eliminates guesswork and prevents duplicate work. For example, technicians can instantly see that a compressor was serviced six months ago, saving time and avoiding unnecessary replacements.

- Improved AMC management: For contractors handling hundreds or thousands of Annual Maintenance Contracts (AMCs), automation ensures not a single visit slips through. One HVAC provider with 1,200 AMC contracts reported that after adopting auto-reminders, they reduced missed appointments by 80%, while customer satisfaction scores improved by 30%.

- Compliance and warranty benefits: Many equipment warranties require proof of regular maintenance. FSM reminders and logs provide documented evidence, helping customers stay compliant and contractors avoid disputes.

2. Smart Job Scheduling 🧑🔧

Assigning the right technician at the right time is critical for customer satisfaction and operational efficiency. Traditional scheduling often leads to mismatched skills, wasted travel time, and customer frustration. Field Service Scheduling Software introduces intelligence into scheduling, matching jobs with the right technician and optimizing routes for maximum efficiency.

- Skill-based assignments: The system automatically pairs jobs with technicians certified for the required task, such as EPA-certified techs for refrigerant handling or specialists for VRF systems. This reduces errors and ensures compliance with regulations.

- Route optimization: FSM software calculates the most efficient routes, cutting unnecessary travel. This not only saves 15–25% in fuel costs but also reduces technician fatigue and carbon emissions.

- Balanced workload distribution: Instead of overloading certain technicians, jobs are evenly distributed. This improves productivity and helps reduce burnout.

- Real-world impact: A service provider with 15 technicians reported doubling daily job completions, from 2 per technician to 4, after implementing FSM scheduling. They also reduced overtime by 40%, saving thousands annually in labor costs.

- Customer satisfaction: On-time arrivals and faster service resolution directly translate into improved Net Promoter Scores (NPS) and long-term retention.

3. Inventory and Consumables Tracking 📦

Inventory mismanagement is one of the most common causes of service delays in the HVAC industry. Technicians often arrive at job sites without the required parts, forcing rescheduling or costly emergency purchases. FSM software prevents this through real-time tracking. See how to track all parts and consumables in the HVAC business effectively to ensure nothing slips through the cracks.

- Centralized inventory visibility: Every part, from filters and compressors to refrigerant cylinders, is tracked across warehouses, vans, and job sites. Managers can instantly see stock levels and avoid shortages.

- Automated replenishment alerts: When consumables like filters or refrigerants reach threshold levels, the system triggers purchase orders automatically, ensuring technicians are always stocked.

- Reduction in duplicate orders: Without a centralized system, teams often reorder items unnecessarily. FSM inventory tools cut down duplicate purchases, saving tens of thousands annually.

- Field technician efficiency: Before heading to a job, technicians can check if required parts are available in their van or warehouse, avoiding wasted trips. This directly improves first-time fix rates.

- Customer experience: By ensuring the right parts are always on hand, businesses reduce rescheduling, which is one of the top causes of customer dissatisfaction in HVAC services.

- Case example: A Chicago-based HVAC contractor integrated FSM inventory tracking and saved $45,000 annually by reducing wasted refrigerants, eliminating duplicate orders, and improving part availability. Their average job completion time dropped by 25%, as technicians no longer had to leave sites mid-job.

4. Mobile Access for Technicians 📱

- FSM mobile apps allow technicians to access service history, checklists, and customer notes in the field.

- Boosts first-time fix rates by up to 30%, as technicians arrive prepared with the right tools and parts.

- Saves 1–2 hours daily by cutting down paperwork, enabling technicians to complete more jobs.

🏆 Best Practices for Effective HVAC Maintenance Schedules

Even with checklists and software, success depends on execution discipline. Top-performing HVAC companies follow these practices:

- Train teams thoroughly: Technicians must be comfortable with FSM apps and digital tools.

- Leverage data-driven insights: For example, equipment in dusty construction zones may need filter changes twice as often as office buildings.

- Standardize checklists: A uniform checklist ensures consistency across a 5-person or 50-person team.

Monitor KPIs: Use dashboards to track SLA compliance, first-time fix rates, and customer satisfaction scores. Learn how to Make HVAC More Efficient Using HVAC FSM Software to maximize these outcomes.

🛠️ Tools Needed for an Efficient HVAC Maintenance Schedule

To implement modern preventive schedules, businesses must invest in:

- FSM Software (Fieldy): Automates scheduling, reminders, and analytics.

- Digital Checklists: Replace paper logs, ensuring accountability and real-time updates.

- Inventory Management Systems: Prevent delays from missing parts.

- Analytics Dashboards: Track KPIs such as technician productivity, job completion rates, SLA compliance, and customer satisfaction.

💡 Benefits of Using HVAC FSM Software for Maintenance Scheduling

Businesses adopting FSM software experience:

- Consistency: Every job follows a standardized workflow.

- Cost savings: FSM adoption typically reduces operational costs by 20–30%.

- Customer loyalty: Scheduled, predictable maintenance builds long-term contracts and reduces churn.

- Scalability: A contractor managing 500 AMCs can scale to 5,000+ clients without multiplying staff.

✅ Conclusion

In 2026, a structured HVAC maintenance schedule is no longer a “good-to-have”; it’s an absolute necessity for staying competitive, sustainable, and customer-centric.

By automating preventive maintenance, optimizing job assignments, and digitizing checklists, Fieldy’s field service management software ensures that HVAC businesses never miss a service call, no matter how busy the season gets.

Want to streamline your HVAC maintenance schedules in 2026? Try Fieldy’s HVAC FSM Software and never miss a service call again. ⬇️

❓ FAQs

How often should HVAC systems be maintained?

A: HVAC systems should follow a structured cycle: monthly inspections for filters and thermostats, quarterly tune-ups for coils, ducts, and refrigerants, and an annual comprehensive service with system audits and part replacements. This schedule ensures efficiency, prevents breakdowns, and extends equipment life.

What are the risks of skipping preventive HVAC maintenance?

A: Skipping preventive maintenance can lead to higher energy consumption, frequent equipment breakdowns, reduced lifespan of HVAC units, poor indoor air quality due to dust and mold, and loss of customer trust in service reliability.

How does HVAC scheduling software improve technician efficiency?

A: It automates job assignments, optimizes routes, and provides mobile access to service history, reducing wasted time.

Can HVAC FSM software help small businesses?

A: Yes. HVAC FSM software helps small businesses by automating AMC reminders, scheduling the right technicians, tracking inventory in real time, and providing mobile access to service history and checklists. This boosts productivity, reduces costs, and enables smaller teams to deliver consistent, professional service.

![HVAC Maintenance Schedule Checklist, Tips, & Tools [ Ultimate Guide 2026 ]](https://blog-admin.getfieldy.com/wp-content/uploads/2025/09/HVAC-Maintenance-Schedule-ChecklistTipsTools-Guide.webp)