👋 Introduction

The question “How do I track all parts and consumables in the HVAC business effectively?” is one of the most frequently asked questions in the world of service- and HVAC-related businesses. The question gets asked often, but it’s the one that makes or breaks you.

Every business experiences cash losses related to inventory management issues, but those cash losses are almost always underestimated. Studies show that service companies are in danger of losing as much as 30% of their technician time to missing or untracked parts. Imagine a team that gets sent to a job site and doesn’t have the refrigerant or thermostat to finish the job—this definitely needs a follow-up visit. It means more labor hours, double the travel expenses, and quite possibly the permanent loss of the client.

Even worse, a disorganized inventory trove uses capital that could otherwise be used to purchase stock that is truly in demand. The 2023 study on HVACR Businesses published in ACHR News shows that due to overstocking, 15-20% of working capital is locked up, limiting the money that could be used to grow the business or deal with emergencies. Stockouts, on the other hand, result in forgone sales and urgent buyouts, which may be 40% costlier than the planned purchases.

Knowing exactly where each component of your parts and supplies is, along with its quantity, isn’t purely organizational. Instead, it speaks to the operational profit of your company, the reliability your clients depend on, and the ongoing stewardship of your company. The following explains:

- The specific HVAC components of inventory that need to be tracked.

- What field service tracking is, how it works, why it matters, and how it can be successfully implemented.

- The problems that HVAC companies experience.

- The best ways to monitor inventory.

- The proven strategies, use cases, and practices that have been validated by the industry.

- How Fieldy transforms inventory management into an opportunity for growth.

If you’re searching for integrated productivity platforms, feel free to consult the comprehensive guide we’ve developed concerning HVAC Field Service Management Software.

🗂️ What to Track in Your HVAC Inventory

The initial action to resolve the query “how do I track all parts and consumables in my HVAC business” is to define what qualifies as inventory. Big-ticket items are tracked in most businesses, but the smaller items are overlooked. The smaller items move faster and incur greater losses if left unmanaged.

🛠️ Parts (High-Value, Low-Frequency Use)

- HVAC units and compressors

- Thermostats and controllers

- Motors and blowers

- Electrical components (wires, capacitors, breakers)

- Ductwork materials

- Refrigerants (R-410A, R-32, etc.)

These are expensive, bulky, and critical for specific jobs. Losing track of them means massive delays and wasted investments.

🔧 Consumables (Low-Value, High-Frequency Use)

- Lubricants and oils

- Tapes (insulation, duct tape)

- Adhesives and sealants

- Screws, bolts, and fasteners

- Cleaning agents and descalers

- Protective covers and gaskets

While consumables seem minor, field studies show they account for 25–35% of recurring material costs. When technicians don’t log usage, your P&L slowly leaks money.

For a deeper breakdown of every part and consumable you should monitor, check our detailed resource on What to Track in Your HVAC Inventory.

🚨 Why Effective Parts Tracking Is Critical for HVAC Field Service

Inventory management directly affects service efficiency. Let’s explore what happens when HVAC businesses don’t take it seriously.

⚠️ Common Pitfalls of Poor Tracking

| 🚧 Challenge | 📖 Details |

|---|---|

| 1. Delayed Jobs |

|

| 2. Return Trips |

|

| 3. Wasted Labor Hours |

|

| 4. Frustrated Customers |

|

| 5. Cash Flow Issues |

|

📉 Business Impact – The Consequences Ripple Across the Organization

| 🚧 Challenge | 📖 Details |

|---|---|

| 1. Profit Erosion |

|

| 2. Scheduling Friction |

|

| 3. Team Frustration |

|

Explore how HVAC field service management software makes HVAC businesses more efficient by helping them overcome these bottlenecks.

📊 Proven Strategies to Track Inventory Effectively

How do I track all parts and consumables in my HVAC business effectively without overwhelming my team? The answer lies in combining technology, process, and training.

1. Use Field Service Inventory Management Software with Real-Time Updates

Cloud-based systems provide live visibility into every warehouse, truck, and job. Technicians can check availability before leaving, request stock, and log usage instantly.

2. Implement Barcode / QR Scanning

Scanning simplifies check-in/out and reduces errors. A study in logistics shows barcode adoption cuts inventory errors by up to 90%. For HVAC teams, it’s the fastest way to prevent loss.

3. Set Par Levels & Automated Reordering

Define minimum thresholds for frequently used items. When stock dips below par levels, the system auto-triggers reorder alerts. No more stockouts of filters during peak summer.

4. Use Cycle Counts Instead of Full Audits

Full audits are time-consuming and disruptive. Cycle counts, small, regular checks, maintain accuracy with minimal downtime. Many HVAC companies cut audit time by 50% using this method.

5. Categorize Inventory Smartly (JIT, VMI, FIFO)

- JIT (Just-in-Time) minimizes storage costs.

- VMI (Vendor-Managed Inventory) lets suppliers handle restocking.

- FIFO (First-In-First-Out) ensures older stock is used before it expires (critical for refrigerants).

6. Train Technicians with Standard Workflows

Inventory software is only as strong as its users. Technicians need clear SOPs for logging consumables and scanning parts. Training prevents gaps and ensures everyone follows the same system.

7. Leverage Predictive Forecasting

Use historical data and seasonal demand trends to stock smarter. For example, refrigerant demand spikes 40% in summer, while furnace parts surge in winter. Forecasting prevents both overstocking and shortages.

To see how inventory tracking also connects with contracts, read our insights on Best Contract Management Software.

📲 How Fieldy Enables Efficient Parts & Consumables Tracking

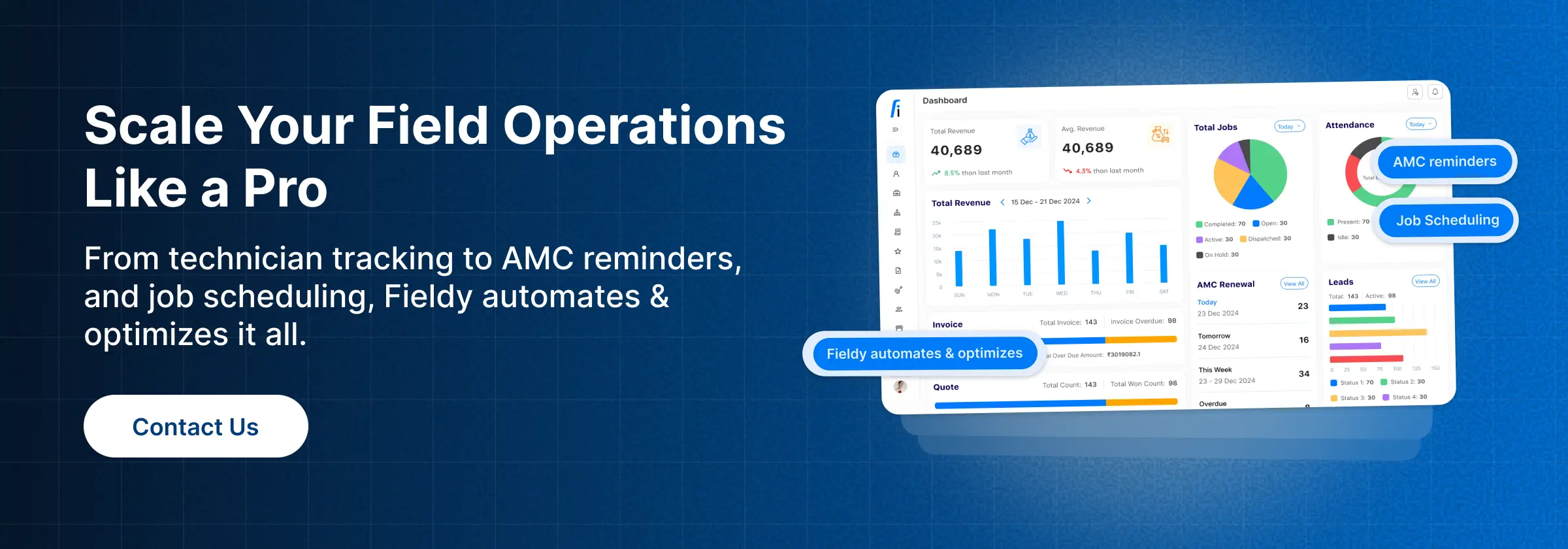

Fieldy transforms inventory management from a liability into a strategic advantage. Here’s how:

- Centralized Inventory Dashboard – View stock across warehouses, trucks, and job sites in real time. Fieldy gives managers a single source of truth, preventing duplicate orders, hoarding, and the “out-of-stock surprise.”

- Mobile-Ready Scanning & Logging – Technicians scan parts with their phones to update inventory instantly. This eliminates paperwork, avoids miscounts, and ensures accuracy, for example, logging a thermostat install deducts it from stock on the spot.

- Par Level Alerts & Restock Automation – Set minimum thresholds for essentials like filters or sealants. Automatic alerts or reorders prevent last-minute supply runs and job delays.

- Integration with Scheduling & Job Orders – Inventory links directly with field service scheduling software and field service invoicing software. Parts are reserved when jobs are scheduled and flow into invoices once completed, saving admin time and ensuring accurate billing.

- Reporting & Audits – Usage reports reveal fast- and slow-moving items, losses, or inefficiencies. Managers can spot trends (like one truck using more consumables) and plan replenishment better while improving financial accuracy.

To explore how workflows connect seamlessly, visit our guide on Field Service Workflow Best Practices.

🕵️ 3 Myths vs. Facts About HVAC Inventory Tracking

Myth 1: “Small businesses don’t need inventory tracking.”

Fact: Even a two-truck operation feels the impact of poor tracking. Missing a single thermostat or refrigerant bottle can delay jobs, waste hours, and frustrate customers. According to Aberdeen research, disorganized inventory contributes to up to 20% lost technician productivity, and that hits small businesses harder because every truck hour counts.

Myth 2: “Consumables don’t matter much.”

Fact: It’s easy to dismiss low-cost items like screws, sealants, or tape. But these “small” consumables often make or break job completion. Losing just $10 in consumables per service call adds up to over $25,000 a year for a team running 10 jobs a day. Tracking them ensures smooth workflow, better forecasting, and improved margins.

Myth 3: “Software is too expensive and complex.”

Fact: Modern solutions like Fieldy’s HVAC inventory management are mobile-ready, affordable, and designed for ease of use. Unlike older systems, they scale with your business, whether you’re running 2 trucks or 200. Plus, they integrate directly with field service scheduling software and invoicing tools, so inventory links seamlessly to jobs, billing, and reporting.

🌍 Real-World Use Cases

Let’s look at practical examples of how HVAC companies use Fieldy to solve inventory problems:

- Residential HVAC Business – Technicians scan filters used at each job. Fieldy auto-updates stock and generates restock alerts, preventing service delays.

- Commercial Service Team – A central warehouse syncs inventory with truck stock daily, reducing emergency return trips by 35%.

- Multi-Location Franchise – Headquarters gets real-time visibility into stock usage across regions, balancing supplies efficiently and ensuring BOM (Bill of Materials) accuracy.

📦 Best Practices Recap

| 🛠️ Strategy | 🎯 Benefit |

|---|---|

| 📱 Mobile scanning & real-time logging | ✅ Eliminates manual errors and ensures accuracy |

| 🔄 Auto-reorder via par levels | 📉 Prevents shortages and reduces capital lockup |

| 📋 Standard workflows & training | 🤝 Improves accountability and minimizes loss |

| 📊 Data-driven forecasting | 📈 Aligns stock with actual seasonal demand |

| 🔗 Fieldy integration | ⚡ Connects inventory with scheduling, dispatch, and billing |

✅ Conclusion

Effectively tracking parts and consumables in HVAC businesses is more than an operational detail; it’s the backbone of efficiency and profitability. Companies that still rely on paper logs or spreadsheets face mounting costs, lost jobs, and shrinking margins.

By adopting modern strategies like barcode scanning, predictive forecasting, and automated reordering, HVAC companies can streamline operations, protect cash flow, and improve customer trust.

Fieldy takes it a step further by connecting inventory with job scheduling, billing, and mobile workflows, ensuring that every technician has what they need, when they need it.

Ready to simplify your inventory processes and stop asking “How do I track all parts and consumables in my HVAC business effectively?” Start today with Fieldy’s field service inventory tracking solution and turn your stock control into a competitive advantage.

❓ FAQs

How do I track all parts and consumables in my HVAC business effectively?

A: The best way is to adopt field service inventory management software. Tools like Fieldy give real-time stock visibility, automate reordering, and let technicians log usage from anywhere. This eliminates errors and ensures smoother operations.

Why is it important to track HVAC consumables separately?

A: Consumables like tapes, screws, and sealants seem minor, but when untracked, they drain thousands of dollars annually. Tracking ensures accurate billing, reduces hidden costs, and keeps margins healthy.

What challenges do HVAC companies face with inventory tracking?

A: Common hurdles include multiple stock locations (warehouses, trucks), unlogged fast-moving consumables, forecasting errors, and technicians forgetting to record usage.

Can software really improve inventory management?

A: Yes. Software like Fieldy integrates with scheduling and invoicing, so every part used is automatically accounted for. Businesses report up to 25% faster job completion after adopting digital tracking.

Does tracking inventory improve profitability?

A: Absolutely. Tracking prevents emergency purchases, reduces return trips, optimizes cash flow, and improves customer satisfaction, directly boosting profitability.

Should small HVAC businesses also invest in digital inventory tracking?

A: Yes. Even small teams face losses from untracked consumables. Affordable platforms like Fieldy scale with your business and deliver quick ROI by cutting waste and delays.