🛠️ Introduction

🔑 Why Work Order Management Matters in 2026

To every service business with a successful history-HVAC, plumbing, electrical, or facilities-it all comes down to work order management. Work orders are structured instructions keeping the teams on the same page, jobs running on schedule, and customers happy.

Yet, many companies today still stick with archaic workflows, paper trails, endless email chains, or spreadsheet juggling to manage their service requests. The result is jobs being missed, or jobs duplicated, worse accountability, and angry customers.

According to a Service Council report, some 43% of field service executives said poor tracking of work order management process flow was the chief reason for customer churn and delays-that did not really help client satisfaction.

That is what makes modern field service work order management relevant. With great work order management, the upheaval is now an organized, trackable, and customer-oriented workflow. With digital tools, such as Fieldy, businesses now have smarter, mobile-ready, and inexpensive solutions to manage their work order system.

Before we dive into work order management best practices, let’s break down what it really means, step by step.

📋 What Is Work Order Management?

Modern Work Order Management Technology Process entails end-to-end management encompassing the capturing of a job request, approval of the job request, assigning a qualified technician to undertake it, supervising the whole work progress, documenting the final results, and learning from the data. This implies that work orders maintain their installation schedule, maintenance activities remain predictable, and emergency repair jobs remain controlled.

Why it matters:

- It ensures that nothing will be missed in the process (no jobs “lost” on sticky notes)

- It lines up the people, parts, and priorities so that technicians arrive prepared.

- It enhances communication with clients through real-time updates and accurate ETAs

- It produces a data trail that can be analyzed to reduce costs and improve first-time fixes.

Field service management with work order management entails installations, repairs, preventive maintenance (planned), and predictive maintenance (condition-based). Many organizations also combine warranty work and vendor job work through a common standard.

🧭 Work Order Management Process (Step-by-Step)

Let’s break down the work order management process into 8 key steps:

1)📝 Request Initiation

A work order starts with a trigger: a customer call, a web form, a preventive schedule, or a sensor alert.

Example: A property manager logs “AHU-3 making noise” via a customer portal. The system auto-tags it as HVAC > Mechanical > Bearings.

2)🗂️ Work Order Creation

Details are captured: asset, location, symptoms, SLA, contact, and photos/video if available. Digital intake prevents retyping and errors.

Insight: Teams that capture asset ID and historical notes at creation cut diagnostic time because techs arrive with context.

3)✅ Approval

A supervisor verifies the request, confirms scope, and checks warranty or contract terms. This avoids wasted truck rolls and out-of-scope surprises.

Tip: Auto-approve routine, low-risk requests; escalate urgent or high-cost ones.

4)🎯 Categorization & Prioritization

Jobs are labeled by type (install/repair/PM), impact (safety, compliance, comfort), and urgency (SLA timers).

Stat insight: Service leaders commonly report 30–40% fewer escalations when SLAs are embedded at this step and visible to dispatch.

5)📅 Assignment & Scheduling

Dispatch matches skills, certifications, proximity, and availability. Intelligent scheduling can cluster jobs to reduce windshield time.

Benchmark: Digital scheduling often trims 10–20% travel time per tech, freeing hours for revenue work.

6)📲 Execution & Tracking

Techs receive the work order on mobile with checklists, parts lists, past notes, and customer contact. Status changes (On the way, In progress, Waiting on parts) are tracked in real time.

Customer win: Proactive SMS/WhatsApp updates reduce “Where’s the tech?” calls and improve CSAT.

7)🏁 Completion & Closure

The tech captures photos, readings, root cause, actions taken, and customer sign-off. If billable, labor and parts flow into an instant invoice; if under contract, the system logs it against the SLA.

Common gain: Teams report fewer invoice disputes when proof of work is attached at closure.

8)📊 Review & Reporting

Supervisors review exceptions (repeat failures, out-of-scope work) and analyze field service metrics and KPIs, first-time fix rate (FTFR), mean time to repair (MTTR), schedule adherence, and warranty leakage.

Example: A retail chain finds 52% of repeat calls are filter-related; they switch to quarterly PMs and cut emergency visits by a third.

This work order management process ensures no request gets lost, costs stay under control, and customer satisfaction stays high.

🚀 7 Best Practices for Smarter Work Order Management

Even the most experienced field service teams run into chaos without structure. The good news? A few proven best practices can transform how your business handles jobs, cutting downtime, improving customer trust, and giving managers better visibility.

1️⃣ Go Digital with CMMS

Paper notes and spreadsheets collapse at scale. A CMMS-powered work order management software like Fieldy centralizes requests, automates workflows, and keeps teams accountable.

💡 Insight: Companies using digital intake see 30% fewer missed jobs and 25% faster cash flow (Service Council).

2️⃣ Log Every Job

Skipping work orders leads to lost revenue and zero accountability. Policy rule: “No WO, no work.” With Fieldy, creating a WO takes seconds, keeping admin light while ensuring a full audit trail.

3️⃣ Standardize Formats

Inconsistent job logs make reporting unreliable. Templates in Fieldy (e.g., AC install vs. compressor replacement) bring consistency, reduce rework, and create credible records.

4️⃣ Add Approval Workflows

High-value repairs or warranty claims need sign-off before work starts. Fieldy’s built-in approvals prevent “free” work slipping in and align tasks with contract terms.

5️⃣ Role-Based Access

Not everyone needs everything. Field service technicians see job tasks, finance sees billables, managers see KPIs. Fieldy’s role-based access cuts clutter, prevents errors, and tightens compliance.

6️⃣ Focus on Preventive & Predictive

Planned maintenance is 3–5x cheaper than break-fix jobs. Predictive monitoring (vibration, runtime, temp) spots issues weeks earlier, like one facility saving $40K downtime costs. Fieldy automates PM scheduling, keeping teams proactive.

7️⃣ Train & Improve Continuously

Work orders double as learning tools. Post-job reviews, updated checklists, and sharing “golden fixes” drive first-time-right culture. Fieldy gives managers real-time job outcomes to coach teams and replicate success.

⚠️ Why Traditional Methods Fall Short

Whiteboards, WhatsApp threads, and paper forms feel fast, until you scale. The cracks show up as:

- Slow response (requests buried in inboxes).

- No real-time visibility (managers guess status).

- Data loss (no photos, no signatures, weak audit trail).

- Revenue leakage (unbilled parts/labor, missed warranty recapture).

- Unhappy customers (inaccurate ETAs, no updates).

Industry surveys frequently link digital work order systems to higher FTFR (often +10–30%), lower travel time, and shorter billing cycles, the trifecta of capacity, customer love, and cash flow.

🤖 Why Fieldy Makes Work Order Management Smarter

📱 Digital-First, Mobile-Ready Workflow

Capture requests, approve, assign, execute, and close, all in one place. Fieldy’s field service mobile application gives technicians the exact checklist, parts, and history on-site, even offline.

Outcome: Fewer calls back to base, more confident fixes.

🛠️ Optimized for Field Operations

Dispatch with drag-and-drop, auto-match jobs to skills and certifications, cluster routes by location, and broadcast ETA updates to customers.

Real example: An HVAC crew re-sequenced routes in Fieldy and reclaimed an extra 45–60 minutes per tech per day.

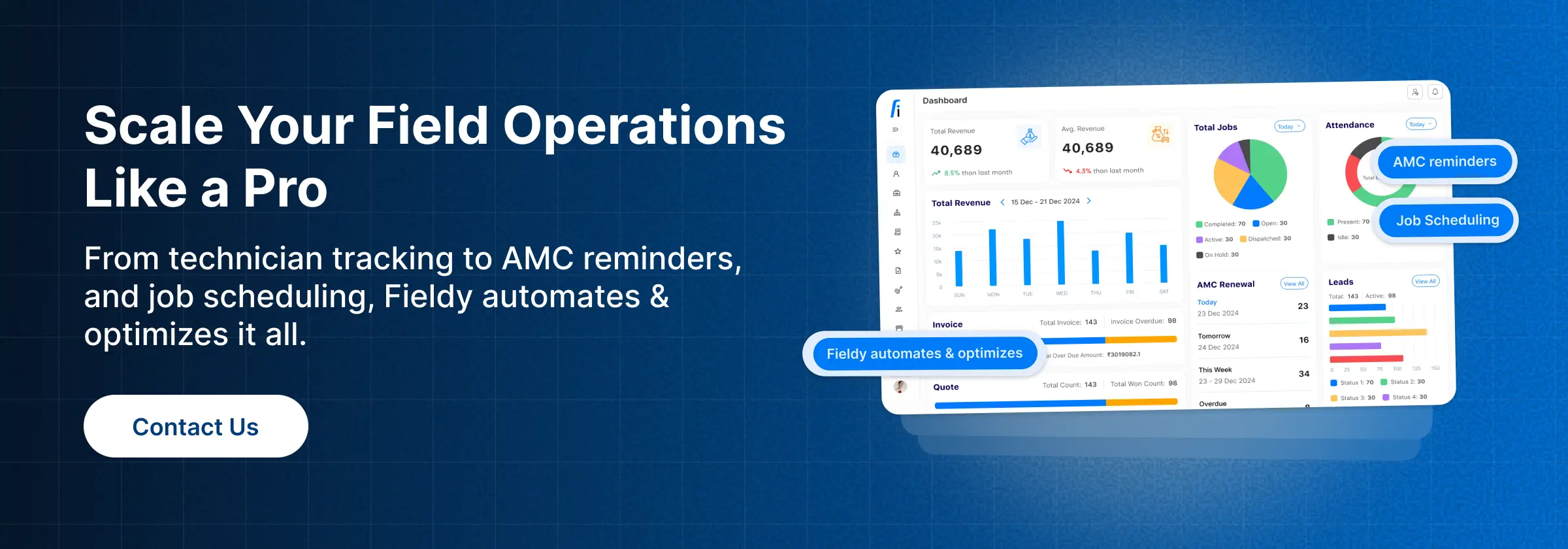

🌍 Integrated Resource Optimization

Fieldy surfaces technician location, availability, and expertise in real time, helping dispatchers factor in traffic windows, SLA clocks, and parts availability.

Impact: Less windshield time, fewer reschedules, higher schedule adherence.

📑 Compliance, Quality & Consistency, Built-In

Use job-type templates, mandatory safety steps, and photo evidence to standardize outcomes. Completion notes and signatures are locked to the work order, making the process audit-ready and perfect for contract SLAs, insurance claims, and quality programs.

This is where the connection to Contract Management Software becomes clear, Fieldy aligns approvals and scope control with every work order, ensuring accountability and compliance across projects.

💸 Affordable & Scalable for SMBs

Enterprise tools can take months and consultants to implement. Fieldy is designed for SMBs: quick to deploy (often same day), simple to learn, and priced so you see ROI fast.

As a bonus, Fieldy natively links work orders to contracts and invoicing, so work → bill happens without copy-paste errors. That’s where Contract Lifecycle Management Software comes in, Fieldy ensures preventive maintenance, renewals, and SLA schedules flow directly from contract terms into daily operations.

📖 What Good Looks Like: A Mini Case Story

The scenario: A 12-tech HVAC company in New York State handled requests via calls and WhatsApp. Jobs vanished on busy days, and invoices lagged a week.

✨ What Changed with Fieldy:

- Customers submit requests via a simple form; every item becomes a work order.

- Dispatch auto-assigns by skill + proximity; routes are clustered by pin code.

- Techs get checklists + photos on mobile and capture signatures on completion.

- Invoices are generated on closure; PMs are auto-scheduled quarterly.

📊 Results after 60 Days:

- First-time fix rate: +18% (checklists + history).

- Travel time: –14% (clustered routes).

- Billing cycle: From 7 days to same-day for most jobs.

- Customer complaints: Down noticeably thanks to ETA messages.

📈 KPIs to Track (and How Fieldy Helps)

- First-Time Fix Rate (FTFR): % of jobs solved on the first visit.

- Mean Time to Repair (MTTR): Average hours from start to completion.

- Schedule Adherence: Planned vs. actual start times.

- Repeat Visit Rate: Indicator of training/parts issues.

- Invoice Lag: Days from completion to invoice sent.

- PM Compliance: % of preventive tasks completed on time.

Fieldy surfaces these in dashboards so managers can course-correct weekly, not quarterly.

🧩 Implementation Tips for a Smooth Rollout

- Start with two job types (e.g., PM visit + emergency repair). Nail templates and checklists.

- Define your approval rules (cost thresholds, warranty checks).

- Clean asset lists and locations before importing, garbage in, garbage out.

- Train in short bursts: 30-minute role-based sessions beat one long lecture.

- Review KPIs after 30 days and adjust templates based on where rework happens.

🎯 Conclusion

In 2026, the winners aren’t just the fastest; they’re the most reliable. A strong work order process brings reliability to every shift, clear requests, smart scheduling, clean hand-offs, proof of work, and data that actually informs decisions. Whether you’re preventing breakdowns or responding to emergencies, digital, standardized, real-time work orders are how small teams operate like big ones.

Fieldy pulls that whole journey into one mobile-first platform, so you can move beyond spreadsheets and whiteboards and deliver work your customers feel confident recommending.

If you’re ready to transform your operations with smarter, digital-first field service work order management, try Fieldy’s field service management software today.

❓ FAQs

What industries benefit most from work order management software?

A: Any field-heavy operation, HVAC, plumbing, electrical, facilities, manufacturing, or even property management. If you juggle installs, repairs, and preventive maintenance, a work order platform pays for itself.

How is work order management different from task management?

A: Tasks are generic to-dos. Work orders are structured jobs tied to assets, SLAs, parts, labor, and billing, so they’re auditable and reportable.

Can small businesses afford Fieldy?

A: Yes. Fieldy is built for SMBs with transparent pricing and quick deployment, so you see value in days, not months.

How does automation improve work order processes?

A: Automation speeds intake and scheduling, prevents missed steps with templates, and accelerates billing by capturing labor/parts at the point of work. Teams often see shorter response times and fewer repeat visits.

Is work order management software difficult to implement?

A: Not at all. Modern platforms like Fieldy are designed for simplicity. Most businesses can get up and running the same day, with minimal training. Unlike enterprise systems that require consultants, Fieldy gives SMBs an easy, scalable solution with quick ROI.